Precision CNC & VMC Machining

Delivering micron-level accuracy for complex automotive and industrial components.

We specialize in machining intricate profiles using high-speed CNC Turning centers and Vertical Machining Centers (VMC). Whether it's high-volume cylindrical parts or complex prismatic blocks, our facility ensures dimensional stability and superior surface finishes.

CNC Turning

Ideal for cylindrical components like shafts, rings, bushings, and threaded collars.

- Diameter: Up to 300mm

- Tolerance: +/- 10 Microns

- Finish: Ra 0.4 - 0.8

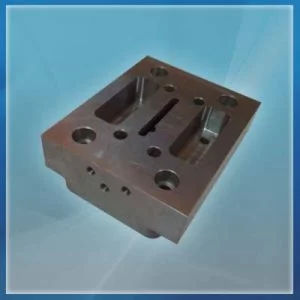

VMC 3-Axis Milling

For prismatic parts like die blocks, manifolds, and housing covers requiring contouring.

- Bed Size: 800 x 500 mm

- Accuracy: +/- 15 Microns

- Operations: Drilling, Boring, Tapping

Production Capabilities

Materials

Aluminum, SS 304/316, Brass, EN8, Titanium.

Tolerances

Standard: ±0.05mm

Precision: ±0.010mm

Batch Size

Prototyping (1-10) to Mass Production (10k+)

Testing

CMM Inspection, Surface Roughness, Thread Go/No-Go.

Have a specialized requirement?

Request Technical Datasheet